SinoForming was built from the ground up by the founder – Wu En Song in 2005. At that time, he was a seasoned industrial engineer at The Franklin Mint and had a ton of experience in the foundry industry and decided it was time he branched out on his own. Starting as a new company with no customers but supported by faith, determination and confidence in himself. Mr Song and his team put their heads together to map out the optimal route to creating a manufacturing facility that provides a layout that was conducive to a cost-effective, lean manufacturing approach to die casting. Since this humble beginning, SinoForming has developed a loyal customer base, achieved substantial growth and became a supplier to some of the world's most admired companies.

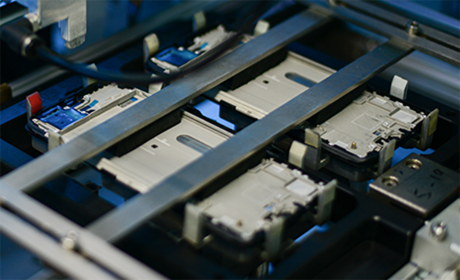

Recognizing that technological growth is the foundation for success, SINOFORMING continues to commit resources and invest state-of-the-art machinery and equipment to remain competitive and become a supplier of choice. Advanced equipment features machines from global leadership in manufacturing technology – GF,Makino, Bühler Toshiba,Frech, Fondarex, RAUCH,Zeiss,Sumitomo,Fanuc,Brother, and X-ray fluorescence spectrometer, laser marking systems, video measuring system, process monitoring, robotics, CNC and latest software including AutoCAD, GstarCAD and Siemens NX.

SinoForming delivers scalable, customizable, and cost-effective component solutions to your doorstep. We deliver a positive impact to our customers by fulfilling their needs through first-class design, engineering expertise, and adherence to globally recognized standards. Our engineering professionals are dedicated to adding values to our clients by improving their design, part performance, decreasing time to market, and lowering manufacturing costs.

As of now, with approximately 4000 dedicated employees and over 150,000 square meters of floor space, SINOFORMING is recognized across the southern part of China as a fully integrated supplier of zinc, aluminum and magnesium die casting, and insert molding.